Gallant Offers "Concept - to - Completation" service from initial Specification, Design, Project Development, Manufacture, Installation & Commissioning. We offers a full product line of equipment and systems designed to meet a wide variety of demanding production requirements. From relatively simple manual systems to sophisticated, programmable, automatic recovery systems for improves efficiency, flexibility and productivity. The latest state of art CAD technology accompanied with a team of skilled, Well qualified & experience engineers, combine to deliver a professional and proved solution to any application through the Design, Manufacturing & onto the installation & final Commissioning at site.

We manufacture highly efficient Powder Coating Plants, which meets the requirements of the customers accordingly. We ensure that latest technology is employed and are appreciated for their corrosion resistance, durability, precision designing, easy installation, optimization of energy & space, easy cleaning and cost effectiveness. These are available in various sizes. Powder Coating Plant is made by quality approved materials that is purchase from leading vendors of the market. We also check these products on various quality parameters.

Efficient, Reliable Turnkey Solutions is our strength — Concept to Environmental abatement. Uniquely Capable, Gallant Designs, Engineers, Manufacture and installs complete custom Manual Batch to Automatic Powder Coating Plant.

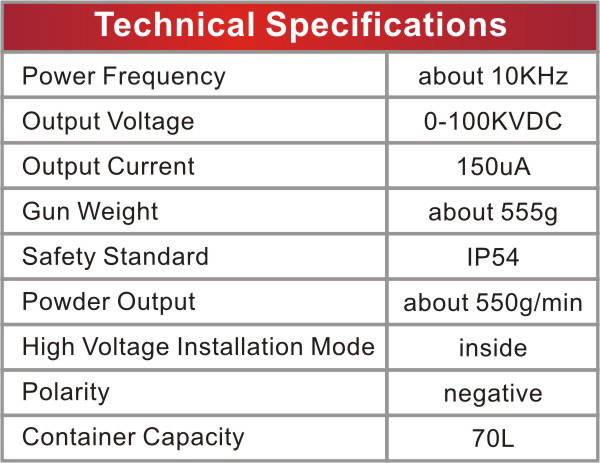

An Extensive Range Of 100 Kv Electrostatic Powder Coating System (Manual & Automatic) That Offer Production Proven Technology And Performance At A Surprisingly Affordable Price.

An Elegant & Ergonomics, 100 KV Electrostatic Powder Coating Equipment (Model : I-Vista & New Ulitmax) has been designed by GALLANT for Manual Powder Coating application. It has multiple Safety features integrated with unique & reputed bought-out item to ensure complete operator friendly & High transfer efficiency with no Back Ionization & Minimum Faraday Cage Effect. These machine provide complete ergonomic , easy to use control features suitable for all type of Job with low & mass voloumn in all type of Powder Coating Plant for Manual & Semi Conveyorised system.

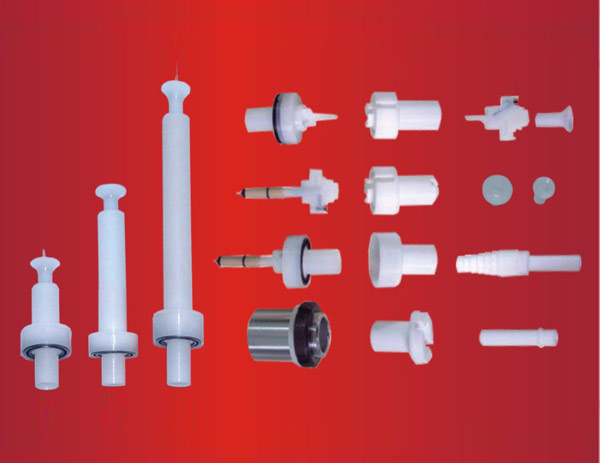

Corona Charge light Weighted Powder Spray Gun integrated with 100 K.V Electrostatic High Voltage Generator Offers Outstanding Performance, Versatility & Excellent Ergonomics, Especially suited for Manual, Automatic & Laboratory System. Compatible with Powder Coating, Fusion Bond Epoxy, Kynar and Flock Coating Application.

Gallant, also manufacture Electro-Mechanical Reciprocator that has capability to vary the speed & stroke to suit the conveyor speed and the jig height. Electrically driven via an AC geared motor, giving a gentle and distinct motion that ensures the best possible coating result with user-freindly control panel so that operator can simply punch in the required stroke length & single speed or multi-speed options.