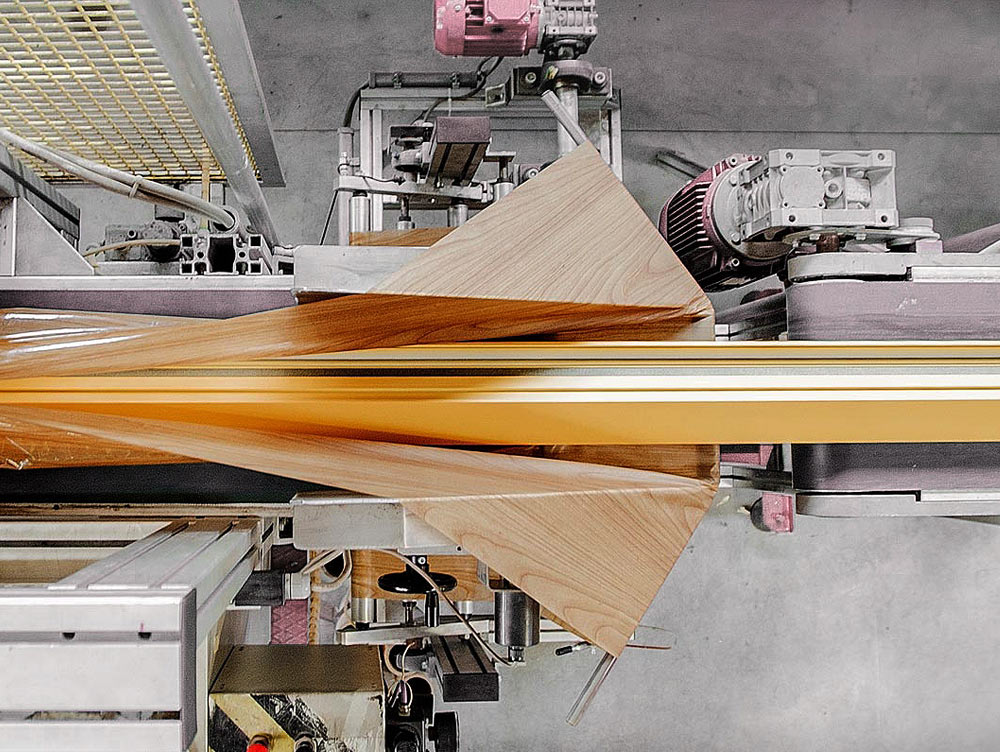

Wood effect sublimation is the industrial process that allows you to faithfully reproduce elegant shades and wood grain on resistant metal surfaces By Sublimation Process (Wood Grain Transfer by Sublimation process) Wood Finish for Aluminium extrusions, Wood Finish On Sheets/ Steel Doors.

With over 20+ years of professional experience and a modern, latest generation aluminum sublimation system, Gallant is the benchmark for the production of wood-effect aluminium profiles.

Our many years of expertise and obsessive care in every stage of processing allow us to ensure the excellent outcome of the finished product, both in terms of aesthetic quality and resistance and durability of the wood-effect finishes created.

The object (Profile, Sheet/Door or accessories) will go under following Process:

The film gets separated from profile and is to be manually peeled off.

For sheets and doors there is separate trolley called as “Membrane Trolley”. At a time two Sheets or Doors can be placed in the trolley fixture and after placing film on sheet it is processed under vacuum as per above process for profiles.