OEM in EAST INDIA in FIBER LASERS

OEM in EAST INDIA in FIBER LASERS

OEM in EAST INDIA in FIBER LASERS

OEM in EAST INDIA in FIBER LASERS

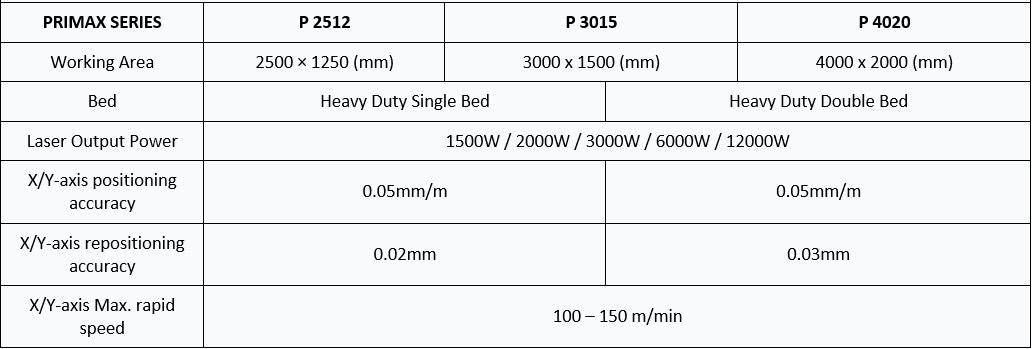

Primax. The highest standard laser cutting machine with best laser cutting source from world's leading manufacturers to fulfil your complete requirement. Primax has the highest mechanical property with Highly Rigid Machine Bed, Compressive Strength and hardness which lasts up to 30 years without any distortions on machine frame. Equipped with various options of 1.5 KW - 12KW laser source from world renowned brands and working area of 2500mm x 1250mm | 3000mm x 1500mm and 4000mm x 2000mm to meet different cutting needs with highest level of finishing & speed. The Primax Fiber laser cutting machine can achieve rapid traverse speeds up to 150 -180 meter/min and acceleration of up to 2G, this guarantees the best quality, precision and highest cutting speed with precision. Likewise, with this model the buyer saves on “production time and cost”.

The Primax Laser Cutting Machine stands as a testament to the exceptional standards set by leading CNC laser cutting machine manufacturers. Designed to meet the highest benchmarks in precision and durability, Primax is engineered for superior performance across various industrial applications.

Crafted with a highly rigid machine bed, the Primax ensures remarkable compressive strength and hardness, allowing the machine frame to maintain its integrity and accuracy for up to 30 years. This durability underscores the commitment of top CNC laser cutting machine manufacturers to providing equipment that delivers long-term value and reliability.

Primax features an extensive range of laser sources, from 1.5 KW to 12 KW, sourced from globally renowned brands. It offers versatile working areas—2500mm x 1250mm, 3000mm x 1500mm, and 4000mm x 2000mm—catering to diverse cutting needs with unmatched efficiency and quality. With rapid traverse speeds of up to 150 - 180 meters per minute and acceleration of up to 2G, the Primax ensures the highest levels of cutting speed and precision, solidifying its position as a top choice among CNC laser cutting machine manufacturers.

By optimizing production time and reducing costs, the Primax Fiber Laser Cutting Machine enhances operational efficiency, making it a valuable investment for any manufacturing operation. Embrace the future of cutting technology with the Primax Laser Cutting Machine and experience the excellence that defines the best in the industry.

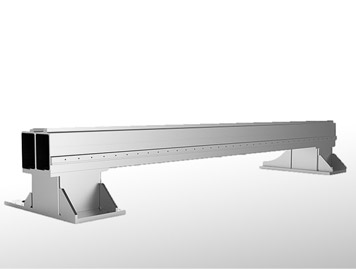

The complete bed frame is fabricated with heavy tubular section and is stress relieved using vibration & heat treatment method. This methods takes hours & even days where the bed sizes are larger. By doing so the molecules in the steel bed achieves nearly 95% even distribution within them and ensure high precision cutting with less than 0.05 um deformation over prolonged usage.

The 3rd Generation Aviation Grade Aluminium Gantry is light weight with high tensile strength, stiffness and durability. It minimizes deformation caused due to environmental changes while maintaining high acceleration up to 2G. The light weight structure ensures optimum part accuracy and speed over the full cutting area by minimising friction & vibration, Saving nearly 40 % Time & Cost over carbon steel gantry.

We have developed modular design over the years for our laser machine which ensure the machine is available in various form factor as per the customer’s requirement. Available in single & double table along with options to get integrated control panel to save floor space.

SigmaNEST the World’s Most Advanced CAD/CAM Nesting Software offers a wide range of customizable & modular features.

SigmaNEST Advanced algorithms Import parts from any major CAD system, automatically sort them into tasks by material and machine, Optimize material usage and machine motion, Post programs to your profile cutting machines and track your productivity from start to finish. It has a variety of options to reduce pierces, save cutting time, and accurately cut your parts. Consequently, this comprehensive approach results in ROI by optimizing material utilization, machine motion, manpower, and data management.